Industrial cleaners, solvents and specialty chemicals derived from biobased resources have come a long way — from the grassroots efforts of the tree-hugging 1960s to the white-coat laboratories of multi-billion dollar companies in the New Millenium.

Gone are the misconceptions that “green” chemistries don’t work as effectively as traditional products. Our policy is to maintain the confidentially of our clients, however, we have provided some application pictures to help illustrate the power of plant-based products.

Oil & Gas

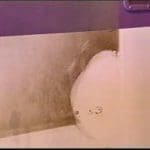

Heavy deposits of asphaltenes were first removed with a spatula, then SC-EZ-Solv Safety Solvent was spray applied and agitated with a plastic brush to loosen the hydrocarbon build-up. After the majority of the asphaltenes were removed, a 50% solution of SC-1000 Aqueous Cleaner was used with a pressure washer as a final step in removing the hydrocarbon soil.

Cleaning large pistons from Wartsila engines in pump station using SC-SuperSolv Safety Solvent, our non-evaporative, water miscible solvent, was sprayed applied and rinsed off with water.

For cleaning petroleum hydrocarbon, SC-1000 Aqueous Cleaner Concentrate at a 50% solution was sprayed on and wiped off. Less product concentration could be used with additional dwell time and/or agitation.

Oil spill barriers were pre-treated with our non-evaporative solvent, SC-EZ-Solv Safety Solvent, to loosen the heavy asphaltene deposits, then a 6% solution of SC-1000 Aqueous Cleaner was used as a final step to remove the hydrocarbon soil and solvent.

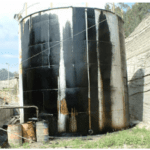

SC-SuperSolv Safety Solvent, our non-evaporative, water miscible solvent was used to removed the polymerized petroleum from the exterior of a tank. For testing purposes, SC-SuperSolv was spray applied, allowed to dwell for 5 – 10 minutes before agitation. The soil was removed with a water rinse.

Parts Washing

SC-1000 Aqueous Cleaner Concentrate is used for parts washing for all ferrous metals, however, SC-Aircraft & Metal Cleaner is specially formulated for non-ferrous metal such as aluminum.

SC-1000 Aqueous Cleaner and SC-SuperSolv Safety Solvent were blended together at an 80/20 blend and diluted to a 50% solution and allowed to dwell for 30 minutes to remove baked on hydrocarbon soil.

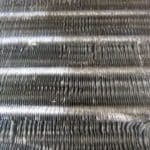

Copper Coil Cleaning

A bath of SC-OmniBrite Acid was used to clean copper fin coils. The coils were allowed to dwell overnight and then rinsed with water in the morning; no agitation was used. Dwell time will vary depending on the soil.

Transportation

SC-Aircraft & Metal Cleaner Concentrate is diluted to a 10% solution for routine cleaning of exterior aircraft surfaces. A higher concentration may be needed for heavier soils such as carbon soot, brake fluid and lubricants.

To remove polymerized hydrocarbon soil from the wheel well of an aircraft, use SC-Aircraft Exterior Wash HD at full strength, agitate with a sponge or nylon brush and wipe cleaning.

A city bus was pretreated with a 10% solution of SC-1000 Aqueous Cleaner when a hydraulic line broke, and a 5% solution of SC-SuperSolv when an advertisement sign was removed before going through the wash tunnel.

SC-1000 Aqueous Cleaner is diluted to a 5-10% solution for exterior cleaning of stainless steel passenger trains using a pressure washer.

Industrial

Various equipment such as a brake cleaning machine at a military depot were cleaned using a 50/50 blend of SC-SuperSolv Safety Solvent and SC-1000 Aqueous Cleaner at a 20% solution for a spray-on, wipe-off application.

For cleaning the honeycombs in a cooling turbine, a side-by-side cleaning trial compared the use of SC-SuperSolv Safety Solvent on the left and the traditional cleaner that was currently used on the right.

Institutional

SC-Exhaust Hood & Filter Cleaner is used at a 50% dilution and allowed to dwell for 5 minutes to clean exhaust hood parts.

Feasibility Study 413

Storage Vessel Decommissioning

We were asked to find a solution for removing and reclaiming petroleum hydrocarbons from storage vessels located offshore. Although the exact type of contaminants are unknown, it is assumed that the contents include crude oil, drilling muds, and/or organic materials with seawater.

We have proposed an 80/20 blend of SC-1000 Aqueous Cleaner Concentrate and SC-SuperSolv Safety Solvent at a 2% solution. The product will be poured into the vessel and allowed to dwell for an extended period of time. The use of heat or agitation is not practicable, and therefore will not be considered.

Day 1: The contaminants were put into the bottom of the beaker and seawater was poured into the beaker. Then the blend of SC-1000 and SC-SuperSolv was added at a 2% concentration.

Day 2: Observed the release of micro-emulsion (gases) and a ring of lighter hydrocarbon factions at the top.

Day 14: Observed the continued release of micro-emulsion (gases) with two distinct rings at the top along with a transitional interfacial separation of hydrocarbon.

Day 15: Agitated the solution to observe whether phase separation will occur again.

Day 34: After the solution was agitated it took 4 days for the solution to start separating again. You can see a ring of the light hydrocarbons at the top along with some of the black hydrocarbons.

Day 34: We also observed reflective particles dispersed throughout the solution. We are not able to determine what the particles are at this time as we do not want to disturb the solution again.

Military

SC-1000 Aqueous Cleaner Concentrate is diluted with water to make a 10% solution for cleaning hand guns and rifles.

AT GEMTEK® , we’re not just order takers -- we’re problem solvers --

Industrial Cleaners, Solvents & Specialty Products

A natural way of denaturing or neutralizing of protein allergens